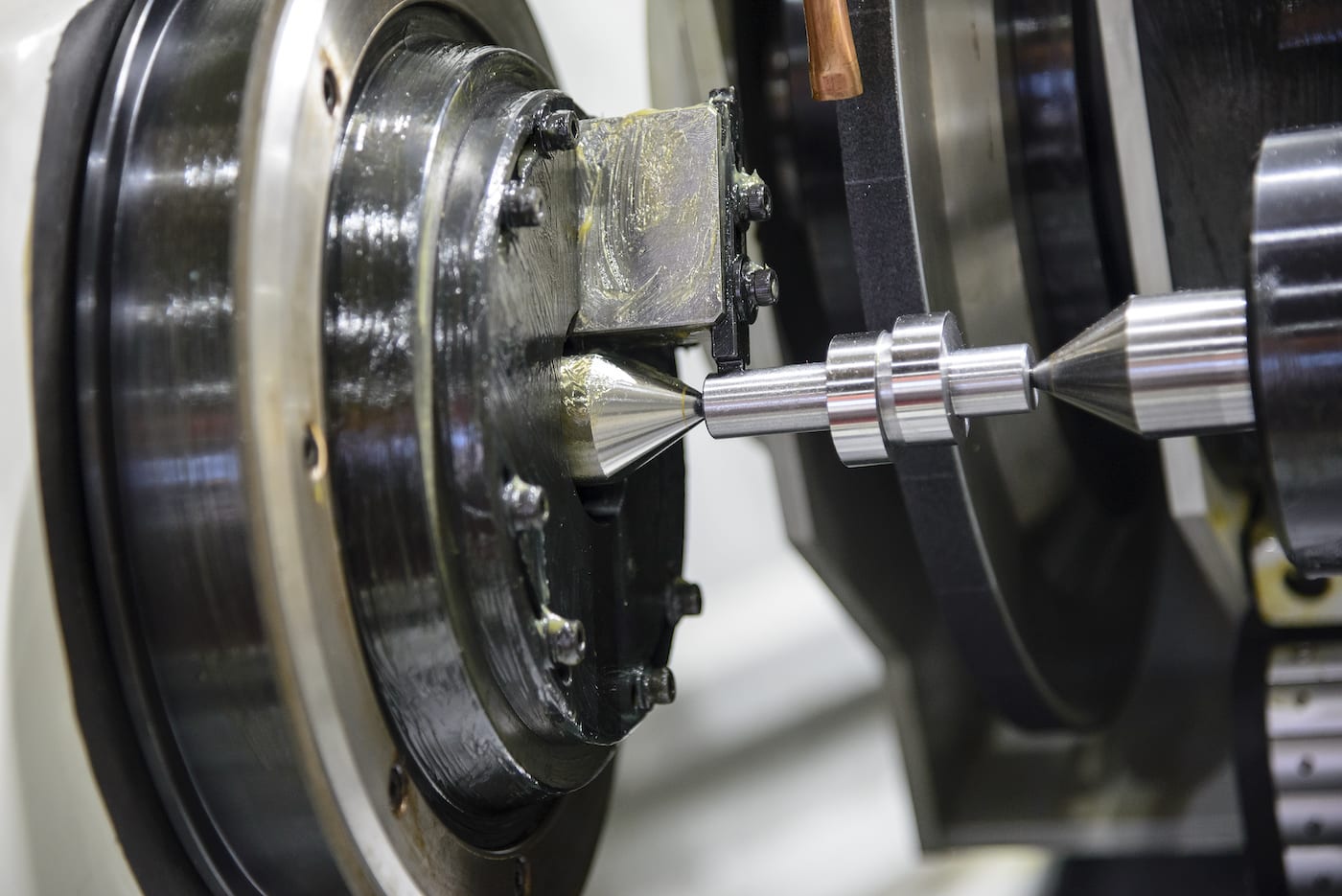

At GMT, grinding both Internal and External Gears is one of our specialties.

The modern equipment we utilize, such as our twin NILES ZE 400S machines, is second to none and capable of producing up to AGMA class 14 gears. Employing the use of dressable wheel technology or CBN wheels for grinding, we are able to offer higher production quantities for our customers while maintaining affordability.

Profile grinding allows individual left and right flank lead and profile modifications. The use of on-board scanning probe measurement allows for accurate corrections to streamline the production process. We are capable of grinding Spur Gears, Helical Gears, Crowned Gears, Cluster Gears, Internal Gears, Herringbone Gears, Splined Shafts, High Speed Pinions, and Bull Gears.

As a part of our process to ensure optimal satisfaction, we also have dedicated off-line climate controlled CNC gear inspection equipment to verify gear quality.

We offer gear grinding only services to our customers as well as complete part-to-print manufacturing.

Have Questions?

For precise and professional gear grinding services, we’re here to help. Feel free to contact us right here or by calling 914-835-0008 today.

Contact Us