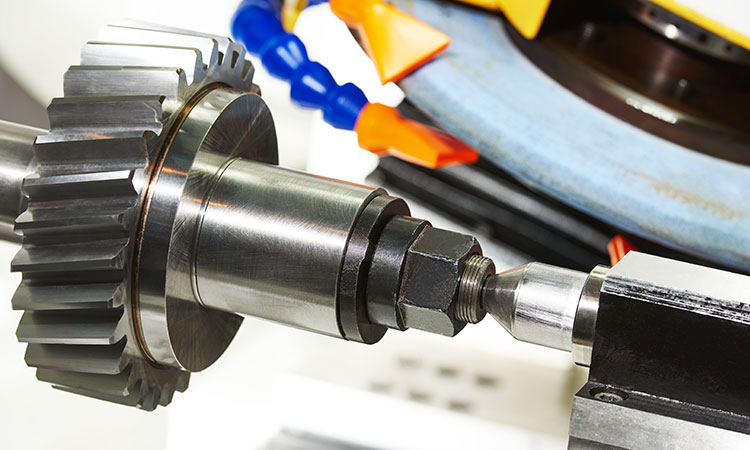

We manufacture Internal and External Spur and Helical Gears, Straight and Spiral Bevel Gears, Crowned and Tapered Gears, Timed Gears, Rack and Segment Gears, Splined components, and couplings. Our fully equipped Machine Shop is also capable of “Lights Out” Mill Turning (Done in One), Precision Cylindrical and Surface Grinding, Cylindrical Honing, Wire EDM Machining, as well as Multi Axis Milling and Turning. All Product is verified in our Climate Controlled Quality Control Lab utilizing gauging traceable to NIST standards.

GMT is dedicated to meeting High Standards and Customer Satisfaction through our unique range of products and capabilities. Our Quality System (QMS) is certified and audited to AS9100 Rev. D and ISO 9001:2015 Quality Standards. We offer our customers complete Part to Print Manufacturing including Heat Treating, Case Hardening, Non Destructive Testing, Plating and Painting to all military and customer specifications. We are driven to employ lean principles as well as FMEA, FAI, PPAP, SPC, Lot Traceability, Marking and Serialization.

Read MoreEnterprises in the aerospace industry rely on Giuliante Machine Tool Inc. for precision machine shop expertise, affordable pricing, and on time delivery for all their prototypes or finished products.

Advanced technology and Cad/Cam programming software ensures 100% accuracy.

You won’t find a more dependable or cost-efficient aerospace machine shop than Giuliante.

All of our finish machining is performed in house and under one roof to ensure top quality.

What started as a two-man operation grew steadily into a 27,000 sq ft facility today.

To learn more about our enterprise and the machine tooling services we offer to the aerospace industry, we encourage you to contact us at 914-835-0008 today.